The American football is the centerpiece of the most popular sport in the United States, and its unique shape and distinct color make it instantly recognizable to any sports fan. Just as the game of football has evolved steadily over the years, the design and construction of the football itself has also changed. Did you know that footballs were not always made from leather? Why are American footballs also called “pigskins?” Let’s learn more about the history of the football and how they’re made, from the late 1800s to today.

The First Footballs Were Made From Inflated Pig Bladders

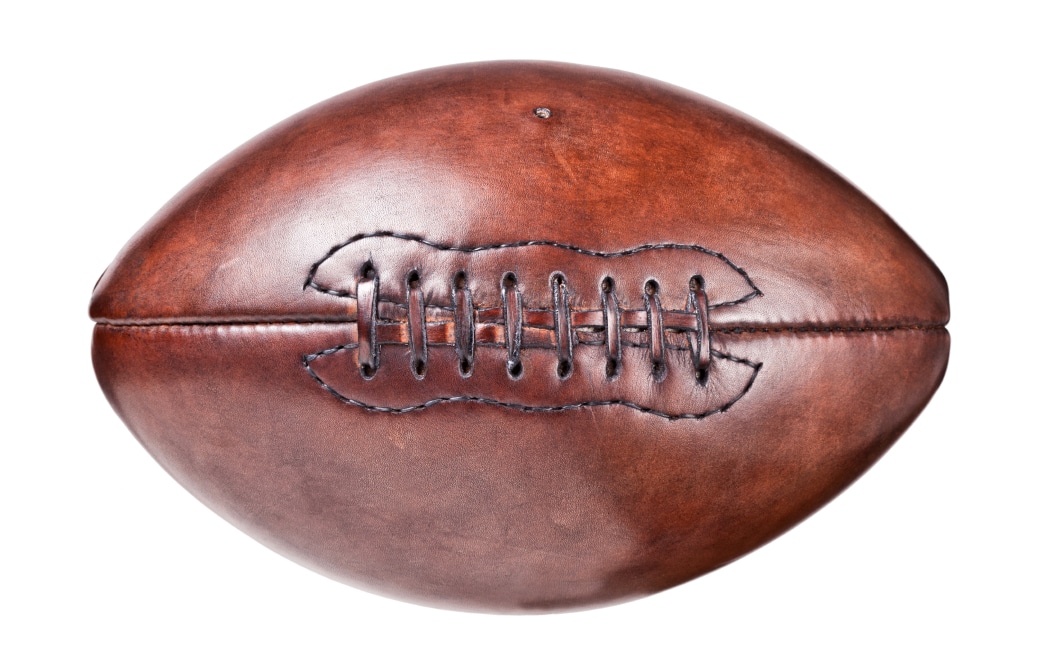

In the 1850s, the earliest version of American football was starting to gain popularity across the country. At this point in time, American football shared many of its rules and gameplay mechanics with rugby, so the ball that these early players used was similar to a rugby ball. These footballs featured a rounded leather exterior with an inflated pig bladder stuffed inside the casing, which helped the ball maintain its shape. The use of pig bladders led to these early footballs being called “pigskins” by players and fans alike, and the term is still used regularly to this day. Early footballs featured a spherical shape that made them easy to kick and run with, but cumbersome to throw.

With the Forward Pass Legalized, the Football’s Shape Changed

The shape of the football would remain largely the same until the early 1900s when collegiate teams started experimenting with throwing forward passes. Keep in mind that while underhand lateral and backwards passes were somewhat common, throwing the football to a receiver down the field was against the rules. But several notable teams started using the forward pass regularly, and this technique exploded in popularity as teams realized how many yards could be gained with every play. This led to the shape of the football being changed gradually over the next few years with each iteration getting slimmer and smaller, making the ball easier to catch and throw.

The Modern Football Comes to Fruition

Now that the forward pass has been fully integrated into the game of football, the game ball’s shape would soon reach its final evolution. Gone were the days of stout leather footballs filled with pig bladders; the slimmer, aerodynamic designs of modern footballs became the ball of choice for players in the 1930s. This decade also saw the standardization of the football’s dimensions to the size and weight that we are familiar with today. Also around this time, the leather used to make footballs would receive its own revisions. Probably the most important change to modern footballs was the inclusion of a pebbled leather surface. The switch from a smooth leather surface to a pebbled one made footballs easier to throw and catch thanks to the increased friction between the ball and the players’ hands. With proper conditioning, these new footballs could achieve unmatched tack and grip.

Since 1993, Big Game Football Factory Has Manufactured Footballs to the Highest Standards

After the football’s shape and size became standardized, the process for manufacturing these footballs remained about the same for the next few decades. Professional and collegiate football would become more popular than ever, which created demand for high-quality, customized footballs that every team could call their own. For 30 years, Big Game USA has been committed to handcrafted footballs for teams all over the United States, from youth leagues to the pros. While many other manufacturers have outsourced their football production overseas, all of our footballs are made right here in Dallas, Texas using domestically-sourced materials. We’re the brand of choice for over 300 high school programs and 115 FBS teams; check out our complete lineup of footballs today and find out why.